TUBE-MAC® Non-Welded Piping Systems

About Tube-Mac®

Tube-Mac® Piping Technologies Ltd. was founded in 1977 as a piping systems

repair and installation business. It has since grown into a progressive

worldwide company with Tube-Mac® offices in Canada, USA, Spain, Austria

and Brazil; distributors and agents throughout North America, Europe,

Scandinavia, Asia and the Middle East.

Advanced Non-Welded Piping Technology

From our worldwide locations, we are capable of providing field technical services to train local contractors or shipyard personnel on the proper use of our pipe fabricating equipment and proper installation of our non-welded piping systems.

Tube-Mac® utilizes technologically advanced non-welded 37° flare and retain ring flanges and PYPLOK® connectors as a more cost effective alternative to welded piping systems. In today's world, skilled high pressure welders are becoming more difficult to find, especially in remote parts of the world. Cleanliness and environmental issues are becoming a major concern in industry. There is absolutely no valid reason that piping systems should be installed in the same manner they were 50 years ago, with high labour costs and inadequate cleanliness practices.

Cost Savings

The advantages gained by Tube-Mac® are not only the saving of time and labour costs but also the elimination of acid pickling and flushing processes, which are required to rid the pipe of the contamination caused by welding.

Extensive Inventories

Our extensive inventories of products and equipment allows Tube-Mac® to deliver materials and services to our customers in a timely manner. These inventories, combined with the availability of Tube-Mac® Project Coordinators and Field Technicians, enables Tube-Mac® to respond quickly to the needs of its customers.

Turnkey Solutions

Tube-Mac® has the ability to provide complete turnkey responsibility for the installation including system flushing to the required ISO or NAS cleanliness level. Tube-Mac® assures that its combination of quality people, quality service and quality products will result in successful projects throughout the world.

PYPLOK Fittings® : A Tube-Mac® Manufactured Product

It’s the weldless threadless way to join pipe/tube.

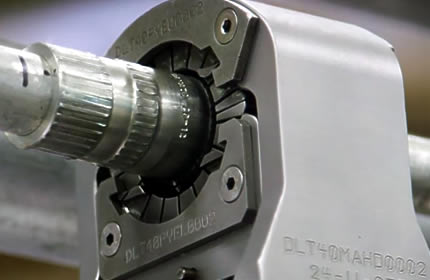

The PYPLOK® connecting system is sparkless and has a long history of successful pipe and tube fabrication in the most demanding environments and systems, where fire safety is essential. Using a portable, hand-held installation tool, fittings are cold worked and permanently compressed onto piping. This process deforms the pipe diameter by a controlled amount, thus forming a permanent leak-tight seal.

Advantages of PYPLOK® sealing characteristics:

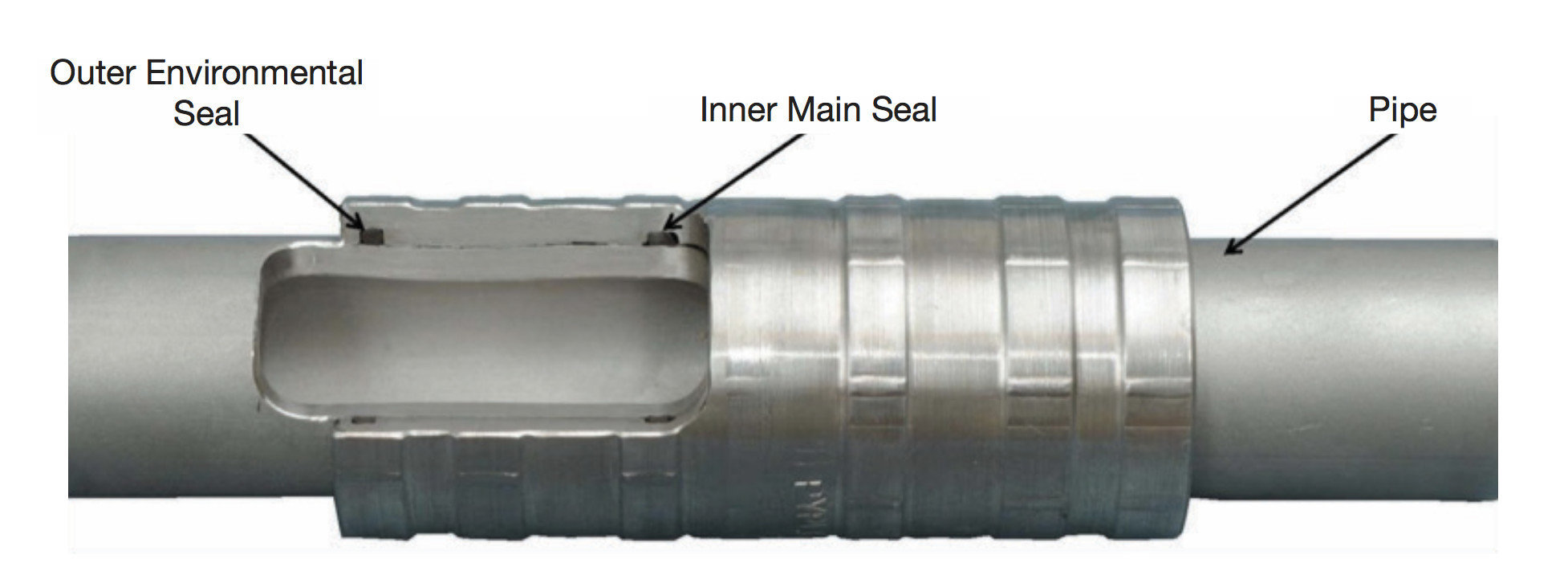

PYPLOK® fittings incorporate unique sealing capabilities. It utilizes four non-metallic o-rings, which make PYPLOK® fittings adaptable to normal pipes, tube tolerances, and surface conditions. There are two O-ring seals. The ‘Inner Main Seal’ is the high-pressure seal. The O-Ring groove which houses this main seal has an annular ridge directly beside the groove which provides additional support upon swaging assuring a fluid-tight connection. The “Outer Environmental Seal” O-ring seals prevent the ingress of fluids and outside contaminants from entering the system.

PYPLOK® fittings are available in Carbon Steel, Stainless Steel Type 316 and 70/30 CuNi (Copper Nickel), and in various shapes: tees, elbows, 45 degree, 90 degree, reducers and custom ends.

Certifications:

API 6FB 3rd Edition Fire Test

ANSI/ASME B31.1 and B31.3

DNV - Det Norske Veritas

ABS - American Bureau of Shipping

CRN - Canadian Registration No. 0A12153.5C

BV - Bureau Veritas

RMRS - Russian Maritime Register of Shipping