Shockwave Metalworking Technologies BV - Triplate

Established in 1962, Shockwave Metalworking Technologies BV has been involved in explosive cladding for more than 40 years. Their unique vacuum explosion technique allows them to handle all types of material combinations and projects of all sizes. This technique is designed to protect the environment and serve the needs of the maritime industry. Shockwave Metalworking Technologies BV is approved as a manufacturer of aluminium/steel transition joints by Lloyd's Register of Shipping and Det Norske Veritas.

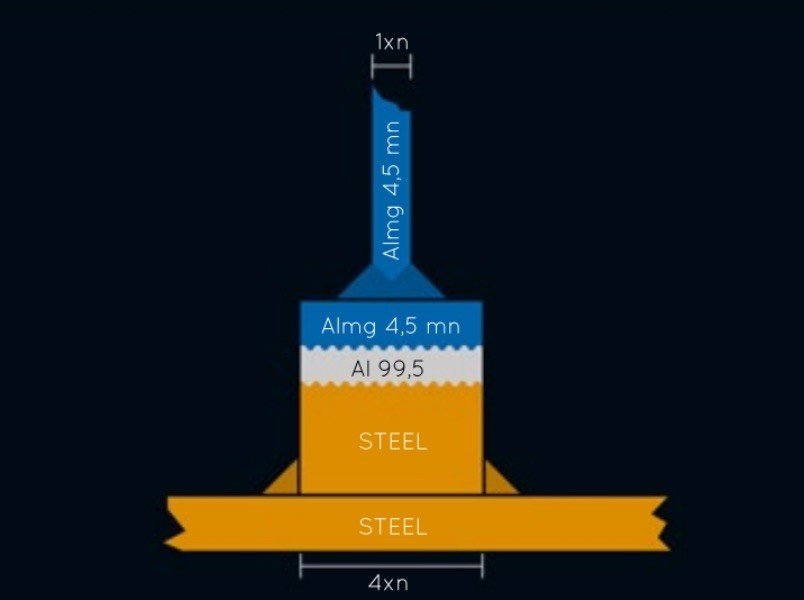

Triplate® is a transition joint composed of three layers: steel, pure aluminium and seawater corrosion-resistant aluminium. These three layers are homogeneously bonded together in a vacuum environment, with the aid of explosives (explosion cladded, welded or plated). This creates a high-quality and longer-lasting material for welding aluminium to steel. Triplate® is easy to process and replaces the conventional nut-and-bolt connection or rivet joints. It is most often used as a transition joint in shipbuilding and offshore for welding aluminium superstructure to a steel hull. Offshore, it is quite common to use Triplate® to weld aluminum living quarters to steel constructions.

Triplate® meets the requirements of all the international standards, including the MIL-J-24445A, for Military applications.

Shockwave Metalworking Technologies' technique of vacuum cladding mitigates the risks and maintenance that come with open-air cladding:

| Open Air Cladding | Vacuum Cladding |

|

Oxides with porosity Oxides initiate fractures Holes initiate corrosion Stress relief treatment due to cold working Variable weather conditions Harder to machine (sawing and bending) |

100% dense Does not apply Does not apply Not necessary since cold working is very limited Does not apply since it is inside Easy sawing and forming due to high ductility |